Handling and assembly of tubes

Flexible parts

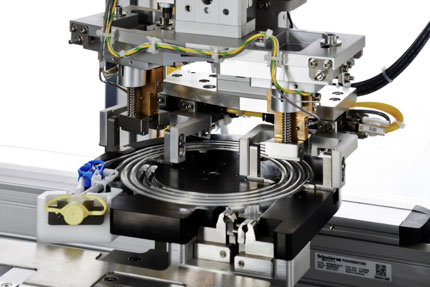

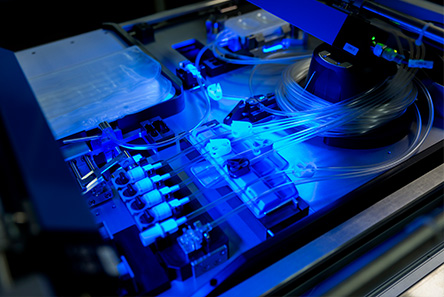

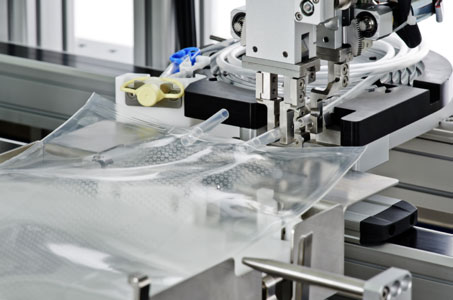

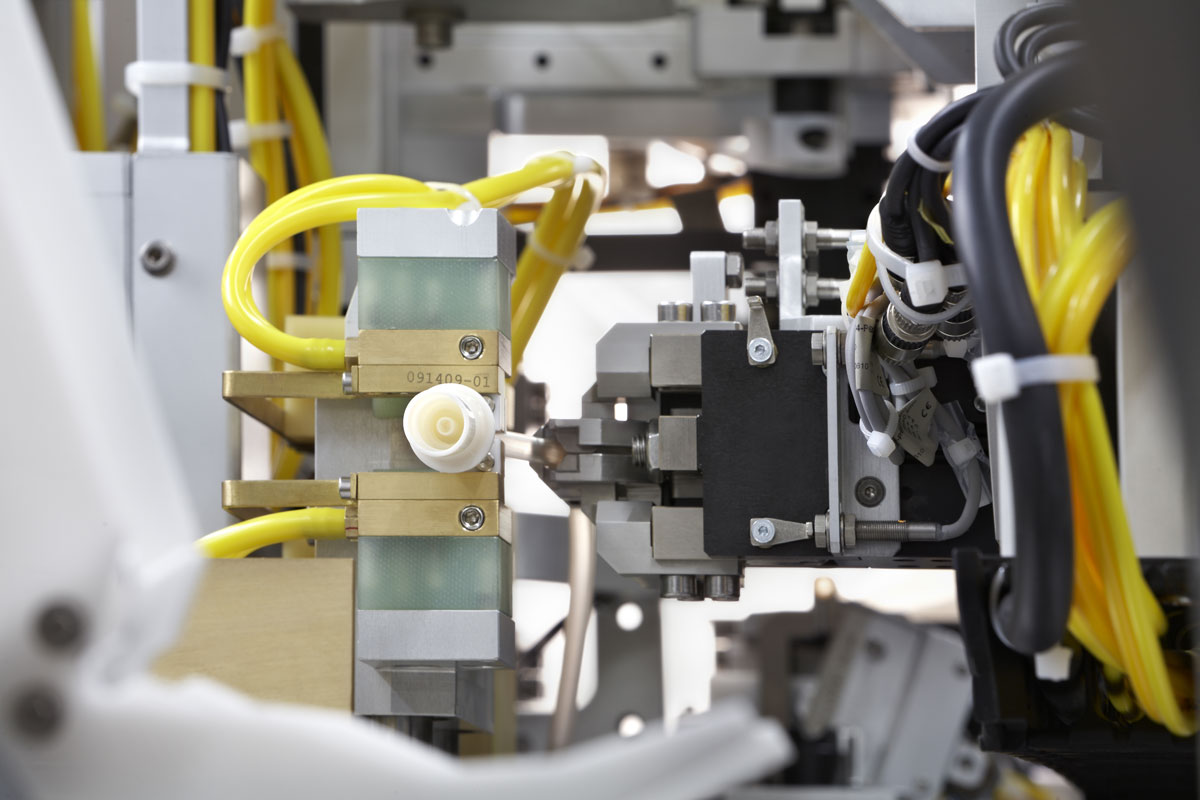

Module-based parts supply and assembly units with different indexing systems are combined to form semi- or fully-automatic assembly lines, depending on the requirements, cycle time or application. Specially developed assembly cells for medical tubing or other components with demanding bending properties ensure fast, high-quality and efficient assembly (quality).

Step by step

Comprehensive tube handling

We master all the necessary handling steps and integrate customer-specific technologies into every system. The application software required for this is entirely designed by our software engineers.

Unwinding

We can unwind tube bundles or reels with a wide range of diameters or tube lengths.

Handling

Tubing with a wide variety of materials can be fed, handled and processed.

Cutting

We use different cutting methods to cut a wide variety of materials.

Bonding

We bond by using solvents with process-safe in-house dosing technology.

Assembling

Robots are used to assemble various components (spike, roller clamps, bags and tubing) onto tubing.

Welding

We use different welding methods such as high-frequency, ultrasonic or thermal welding.

Banding

We offer fully automated, edge-protecting and time-saving banding solutions.

Printing

We use inkjet, laser, tampon and thermal transfer printing and generate DMC/barcodes.

Tube Handling

You are looking for a partner

to help you with your project?

Benefit from our experience now and contact us.