Technologies

Experience and modularity in automation

Thanks to years of further development, our applied technologies can be regarded as modules. We thus guarantee the highest degree of adaptability to the respective customer-specific automation process. This modular system enables us to respond flexibly to all applications and to implement different levels of automation.

Modular technology

Flexible combination options

To illustrate our core competences in automation technology, we have compiled an overview of the technologies most frequently used by us below.

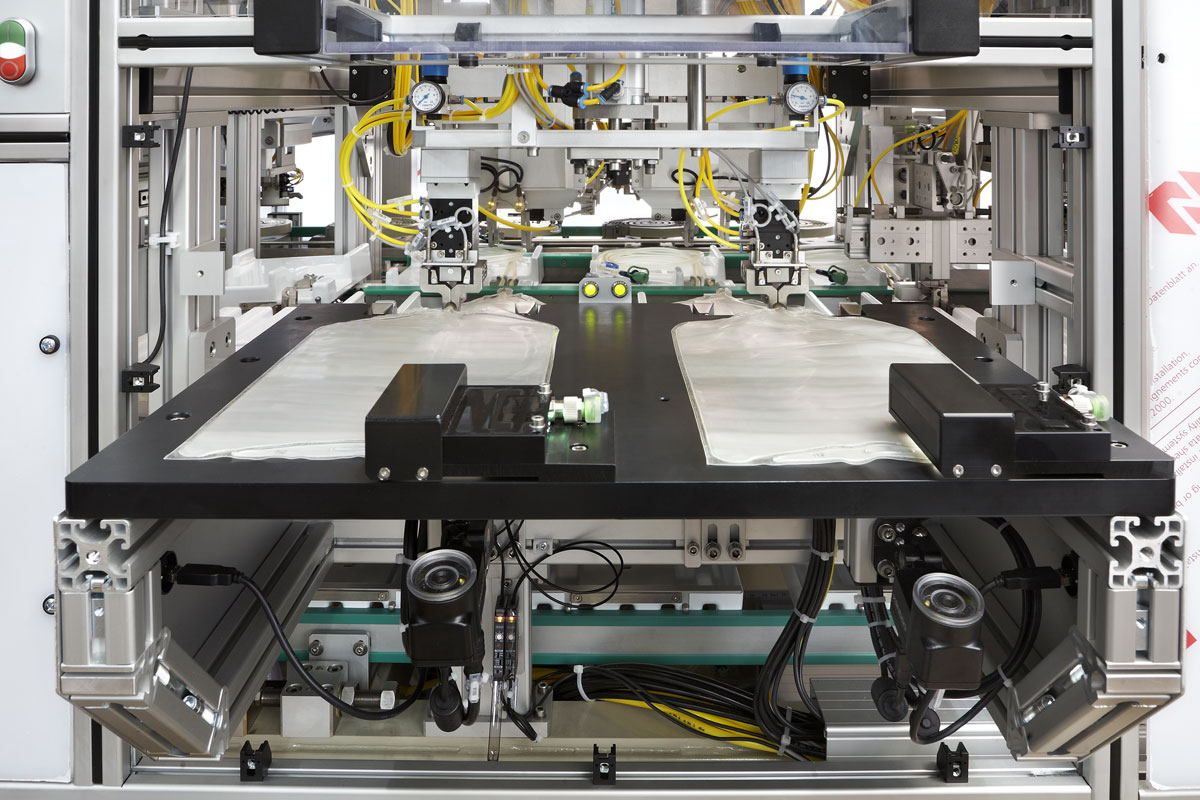

Assembly of flexible parts

Robotics & Gripper Systems

Robotic systems are used to ensure flexible handling and efficient/safe assembly of the components.

Flexible parts

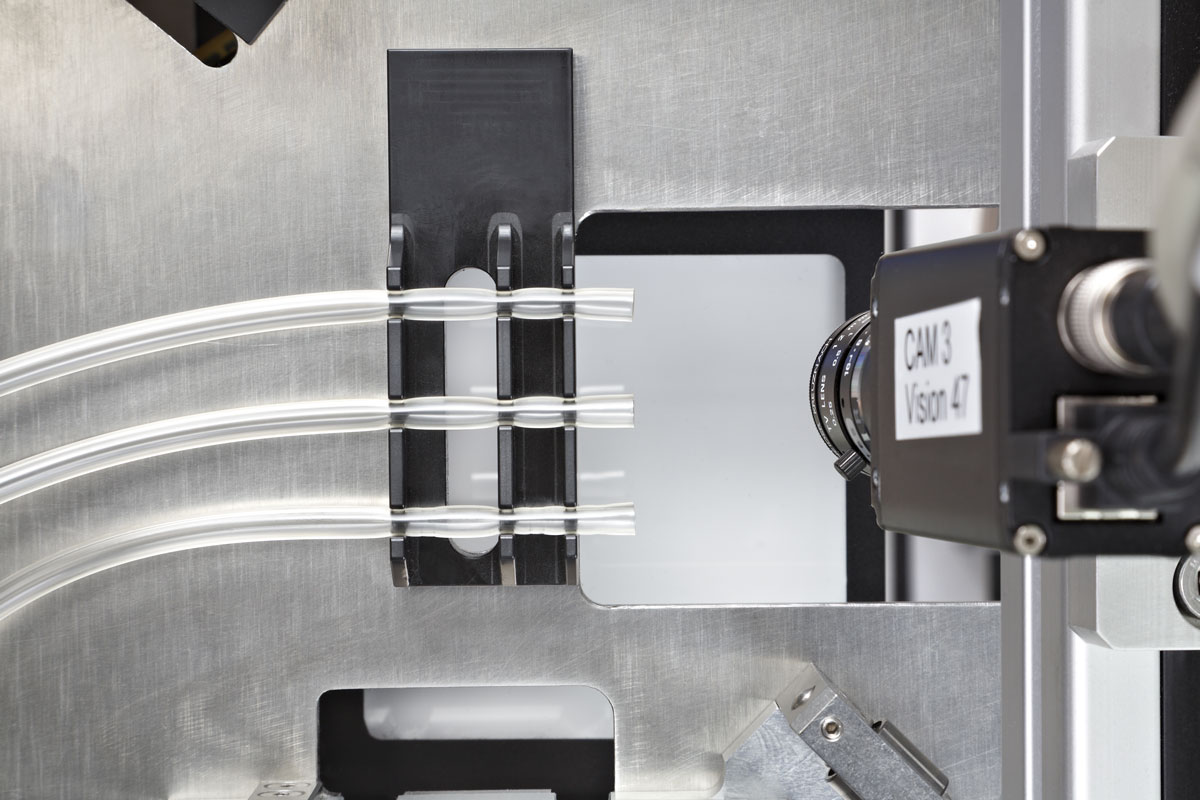

Tube Handling

Tubing is due to its flexibility a difficult product to handle. Through our many years of experience we understand all the necessary handling processes.

Volume-independent under sterile conditions

Filling Technology

The bags/containers are filled automatically and monitored by flowmeters.

Robot-based flex feeders

Feeding Technology

Our robot-based flex feeders are equipped with vision technology. They are particularly suitable for feeding and handling components of different geometries and colours.

Tube on tube or component

Connection & Separation Technologies

Our connection and separation technologies enable us to realise “tube to tube” or “tube to component” connections.

Vacuum or pressure test

Leak Testing

By implementing a physical testing process in your system, you will meet the highest quality standards.

The seeing robot

Vision Camera Systems

Vision technology is used for handling, recognition as well as for control purposes. This technology enables the “seeing” robot to recognise and safely pick up parts of different geometry or colour.

In-house user interface

HMI - Human Machine Interface

With our in-house HMI technology, we offer appealing and ergonomic operating comfort for your system solution in accordance with current VDMA guidelines.

Control systems

Image Processing

To meet all quality requirements, our systems check all components for colour, position and geometry before they are further processed.